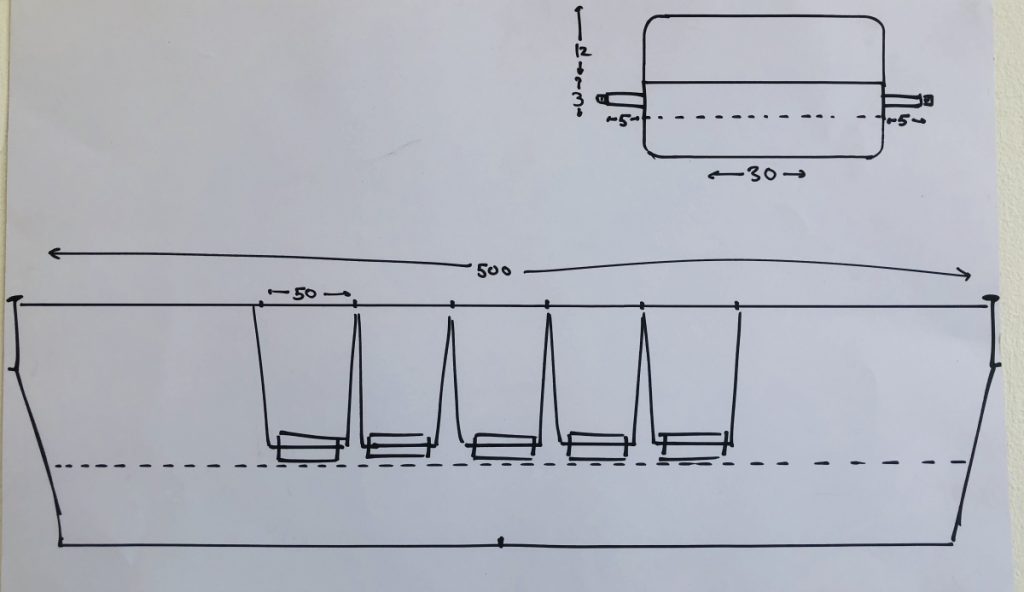

The amended design for the water wheels below has sizes in cm included. The paddles will be the same width but they will be taller. I plan to make a wheel with 12cm tall paddles but also one with 15cm tall paddles. These will be tested side by side to judge the best turning ability and visual impact. It is hoped a taller size will ensure they turn reliably in slow water. The vertical wires will be separated by 10cm more at the top than at the bottom to ensure they don’t get tangled or limit the turning of the paddles but also to keep the paddles close enough together for a good visual effect. I plan to get two paddles made at this point rather than the full five, to create enough to test the layout but to save resources in case the sizing needs adjusting.

I sent this design to an engineer to get his thoughts on the design and suggestions on dealing with the wire sag. His suggestion was to include a hollow steel tube on the vertical wire, which would provide a perfectly horizontal line for the paddles, hence all the vertical wires could then be the same length. He also highlighted that the anchors on the banks need to be firmly located as five water wheels will generate quite a force. I will therefore source a steel tube, which will need to be 2.5m long and I also need to consider how to attach the wires to the tube, I could drill small holes in it to pass the vertical wires through or put clamps on the tube to hold the wire.

The components below were ordered from Express Wire Rope. The strainer will help straighten the vertical wire once the stakes are in the ground and I purchased some thimbles which I thought may provide a way to hold the wire around the axles of the paddles, and minimise friction. The spiral ground spikes were thought to be the best way to reliably secure the vertical wire as they will be very difficult for the current to pull them out of the ground.

Summary & next steps

When all this kit arrives the two full size water wheels can be constructed. In parallel with this exercise, I’m also getting a new set of paddles laser cut so these will need building as well. I’m fairly confident that this proposed design will work correctly but the key issue will be friction where the wire connects to the paddles. I may need try alternate ways to connect the wires if this is an issue.